What Does a Metal Slitter Do?

What Does a Metal Slitter Do?

There are a lot of important factors that must be considered during your search for a reliable service center. These include quality of materials, customer service, and the secondary services. Metal slitting is one of the most useful secondary services that you can get.

How Metal Slitting Works

A metal slitter basically takes wide coils and cuts them down into narrower widths. The process can be performed for the purpose of inventory or if the customer needs a more specific width. The process of sheet metal slitting calls for specialized machine. Once done properly and correctly, it paves the way to faster and more exact additional processing.

Advantages of Sheet Metal Slitting

There are many benefits you can enjoy if you let a service provider handle the work of metal slitting. Some of these include ensuring consistency of the products, cutting back the amount of scrap, and achieving tight tolerances. Also, when you buy materials that are precut to the specific width of your final product, it means that you will not lose any material to edge trimming that is very common when shearing sheet metal.

Top Reasons to Choose Professional Metal Slitting

Metal slitting is a unique machining service where wide coils get cut down into widths that are narrower and more exact. This requires the use of specialized machinery and equipment. Metal slitting done the right way can speed up additional processing and ensure better precision.

Discussed below is a more in-depth explanation of the reasons why you can save more time and make the process easier if you work with a metal slitter:

- Retain Tight Tolerances

For situations in which it is necessary to have a tight tolerance, metal slitting comes in handy. The thicknesses of metals can affect how you can machine and tool a certain material, so your process of manufacturing can help identify its slitting requirements.

For example, customers who will use injection molding can take advantage of materials that have tighter tolerances since they will also have more flexibility throughout the processing.

- Use a More Consistent Product

More than making further processing easier, metal; slitting can also allow more consistent products. Materials with more consistent measurements can be fed more easily through the processing equipment. It can effectively help save time that might have been spent otherwise on size maintenance, machine setup, and supervision.

- Reduce Scrap or Waste

When you purchase metal that is slit near your final size, only a small amount of what you bought will end up as waste or scrap. There are even customers who use width of the slit as their final width so that they don't lose any edge trim as they would if they will use sheering sheet metal.

Based from all of the above information, it is easy to see why working with a metal slitter makes perfect sense. When you have your metal materials slit to the specific width suitable for your application, this can help the project run smoother and finish faster.

Mini Slitting Line

Mini slitting line is a line used to slit wide-sized coils into many narrow width strips.

Slitting Line Customized

Slitting line customized type could combine multiple ideal designs into a tailor-made line for each client.

Rotary Slitter knives

Rotary Slitter knives are manufactured from a wide range of fine materials including Tool Steel, High Speed Steel, and Tungsten Carbide.

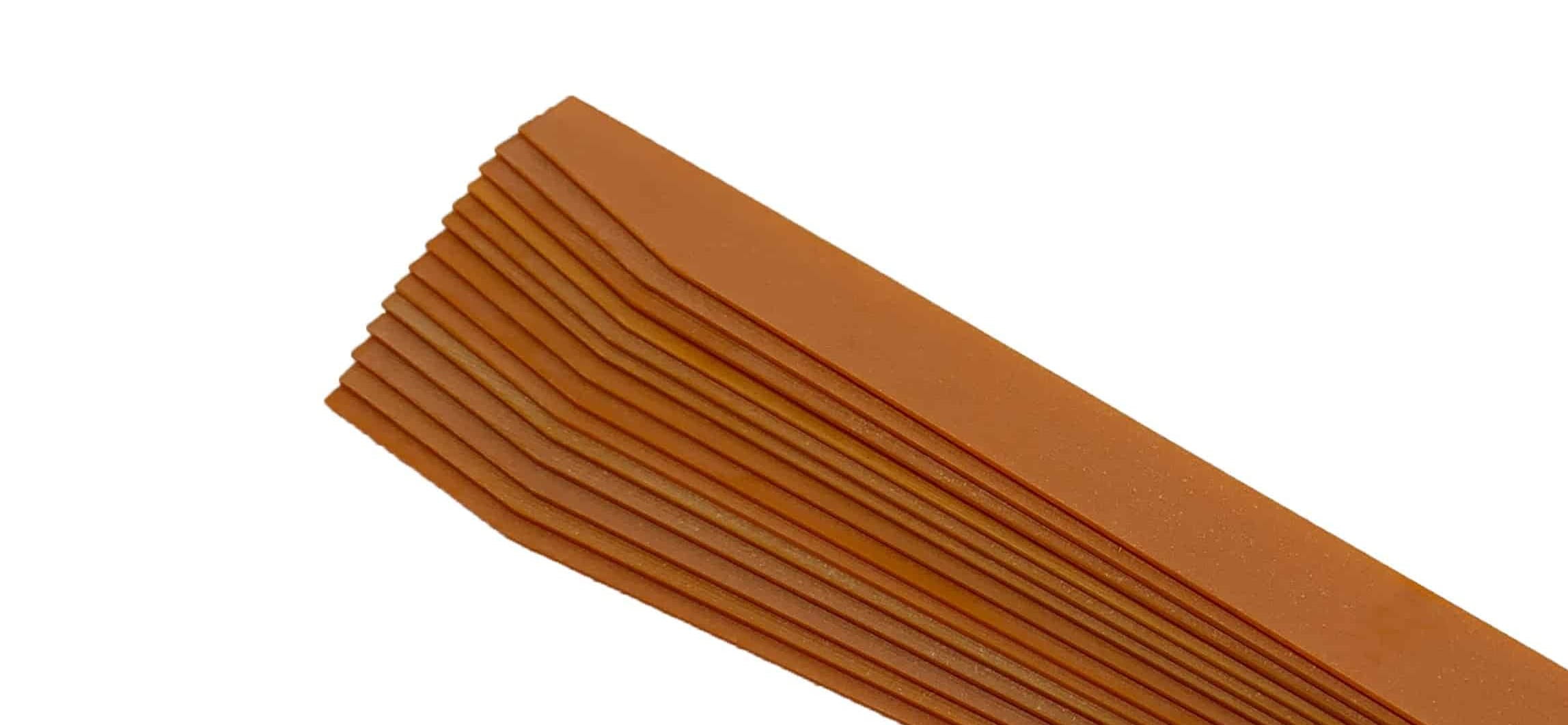

Precision Spacer | Shim

Precision spacers and shims are mainly used in precision slitting machines, and can also be assembled on various machine components that require precise dimensions. Design and manufacturing can be discussed according to the dimensions required by customers.

Slitting Tools and Equipments

TOA DR provides all kinds of slitting tools for different requirements.

留言

張貼留言